Originally printed in the National Geographic Magazine - October, 2007

By Joel K. Bourne, Jr.

National Geographic Staff

When Dario Franchitti steered his sleek, 670-horsepower, orange-and-black Indy car to victory at this year's Indianapolis 500, the ebullient Scotsman chalked up an odd footnote in sports history. He became the first driver ever to win the iconic American auto race on pure ethanol—the gin-clear, high-octane corn hooch that supporters from midwestern farmers to high-ranking politicians hope will soon replace gasoline as America's favorite motor fuel.

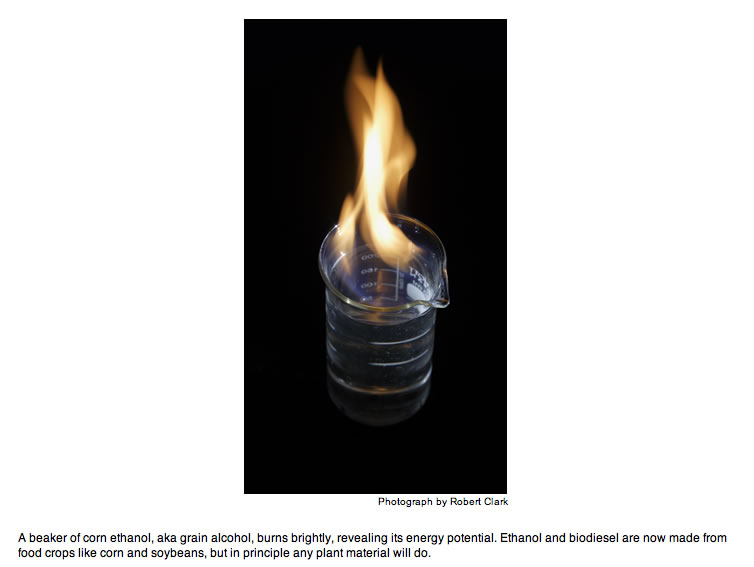

Indy's switch back to the old bootlegger's friend is just one indicator of the mad rush to biofuels, homegrown gasoline and diesel substitutes made from crops like corn, soybeans, and sugarcane. Proponents say such renewable fuels could light a fire under our moribund rural economy, help extract us from our sticky dependence on the Middle East, and—best of all—cut our ballooning emissions of carbon dioxide. Unlike the ancient carbon unlocked by the burning of fossil fuels, which is driving up Earth's thermostat by the minute, the carbon in biofuels comes from the atmosphere, captured by plants during the growing season. In theory, burning a tank of ethanol could make driving even an Indy car carbon neutral.

The operative word is "could." Biofuels as currently rendered in the U.S. are doing great things for some farmers and for agricultural giants like Archer Daniels Midland and Cargill, but little for the environment. Corn requires large doses of herbicide and nitrogen fertilizer and can cause more soil erosion than any other crop. And producing corn ethanol consumes just about as much fossil fuel as the ethanol itself replaces. Biodiesel from soybeans fares only slightly better. Environmentalists also fear that rising prices for both crops will push farmers to plow up some 35 million acres (14 million hectares) of marginal farmland now set aside for soil and wildlife conservation, potentially releasing even more carbon bound in the fallow fields.

The boom has already pushed corn prices to heights not seen in years, spurring U.S. growers to plant the largest crop since World War II. Around a fifth of the harvest will be brewed into ethanol—more than double the amount only five years ago. Yet such is the thirst for gasoline among SUV-loving Americans that even if we turned our entire corn and soybean crops into biofuels, they would replace just 12 percent of our gasoline and a paltry 6 percent of our diesel, while squeezing supplies of corn- and soy-fattened beef, pork, and poultry. Not to mention Corn Flakes.

Still, the prospect of amber waves of home-grown energy crops is too seductive to ignore, especially given the example of Brazil. Thirty years after launching a crash program to replace gasoline with ethanol from sugarcane, Brazil announced last year that thanks to ethanol and rising domestic oil production, it had weaned itself off imported oil. Investors, led by superstar CEOs Richard Branson of Virgin Atlantic and Vinod Khosla of Sun Microsystems fame, have bought into the vision, sinking more than 70 billion dollars into renewable energy companies. The U.S. government has ponied up hefty ethanol subsidies, and President Bush has proposed over 200 million dollars for research, with a goal of replacing 15 percent of our projected gasoline use with ethanol and other fuels by 2017.

"We can create ethanol in an incredibly dumb way," says Nathanael Greene, a senior researcher with the Natural Resources Defense Council. "But there are many pathways that get us a future full of wildlife, soil carbon, and across-the-board benefits." The key, Greene and others say, is to figure out how to make fuel from plant material other than food: cornstalks, prairie grasses, fast-growing trees, or even algae. That approach, combined with more efficient vehicles and communities, says Greene, "could eliminate our demand for gasoline by 2050." A century ago, Henry Ford's first car ran on alcohol, while Rudolf Diesel fired his namesake engine with peanut oil. But both inventors soon discovered that "rock oil," when slightly refined, held far more bang per gallon than plant fuel, and was cheap to boot. Oil soon left plant fuels in the dust. Only in periods of scarcity—like the OPEC oil embargo of 1973—did the U.S. and other countries turn back to ethanol, mixing it into gasoline to stretch supplies.

It wasn't until 2000 that fuel alcohol staged a major comeback, largely as an additive in less polluting gasoline blends. For years, ethanol producers had enjoyed heavy subsidies and protective tariffs on imports, while Archer Daniels Midland, the largest U.S. ethanol producer, advocated mixing ethanol into motor fuel. But ethanol ran into stiff competition with the oil industry's own additive, methyl tertiary-butyl ether (MTBE).

Then MTBE, a suspected cancer agent, began turning up in aquifers, prompting many states to ban the chemical and suddenly creating a two-billion-gallon market for ethanol. Recently, with the Middle East in turmoil and oil security once again a hot issue, Congress gave the ethanol industry another boost, extending the tax credits and tariffs while requiring that 7.5 billion gallons (28 billion liters) of the nation's fuel come from ethanol or biodiesel by 2012. (That figure could rise to 60 billion gallons, 227 billion liters, by 2030 if some senators have their way.) The biofuels boom was on.

Ethanol enthusiasts point out that the oil industry has also reaped huge subsidies for decades, including billions of dollars a year in tax breaks, as well as tens of billions of dollars annually to defend oil fields in the Middle East—even before the war in Iraq. Not to mention the untallied costs to health and the environment of pollution from cars, trucks, and the oil industry itself. And while oil subsidies flow into the hands of the wealthiest companies in the world, ethanol subsidies are fueling a renaissance in small heartland towns with names like Wahoo, Nebraska.

By this summer, with Nebraska's 16 ethanol plants gearing up to consume a third of the state's crop, corn prices had doubled, briefly topping four dollars a bushel, and growers were looking forward to the best profits in memory. "This is the first year I've planted all corn and no beans," says Roger Harders as he finishes lunch at the Wigwam Café in Wahoo. He also has cattle that this year will eat a lot more grass than four-dollar corn. "You're almost tempted to get out of the cattle business and sell your corn outright."

Gary Rasmussen, co-owner of the local Case-IH implement dealership, sold ten new corn harvesters at upwards of $200,000 each from December through February, twice as many as usual, and his tractor sales are up as well.

A computer screen showing the latest corn prices is on prominent display on the sales floor. "Anytime you see a surge in commodity markets, you see a brighter future," says Rasmussen. "Ethanol is going to be a real driver." Despite the boom, it's hard to fill up with ethanol in the U.S. It's still mainly a gasoline additive. Only about 1,200 stations scattered mostly across the corn belt sell ethanol, in the form of E85 (85 percent ethanol, 15 percent gas), which can be burned only in specially designed engines. Ethanol delivers 30 percent fewer miles a gallon than gasoline, but at around $2.80 a gallon in the heartland, it is competitive with $3.20-a-gallon gas. Since the U.S. has no major pipelines for ethanol, transportation by truck, rail, or barge drives up the price elsewhere. But more ethanol plants are popping up all the time. Christine Wietzki, a former farm kid from western Nebraska, is technical manager for one of the newest and most advanced ethanol plants in the country, the E3 BioFuels plant in tiny Mead, Nebraska, population 564. She's spent much of her young career turning food into fuel and believes it's a good deal all around. "If we don't have to export corn and can use it to get off foreign oil, that's fantastic," she says. In a cold spring downpour, Wietzki shows off the plant, a cluster of new white buildings, tanks, and a grain bin rising from thick gray mud next to a pungent, 30,000-cow feedlot.

Much of what happens in its tanks and pipes is typical of any large distillery—after all, people have been turning grain into alcohol for eons. The corn is ground, mixed with water, and heated; added enzymes convert the starch into sugars. In a fermentation tank, yeast gradually turns the sugars into alcohol, which is sepa srated from the water by distillation. The leftover, known as distillers' grains, is fed to the cows, and some of the wastewater, high in nitrogen, is applied to fields as a fertilizer.

The process also gives off large amounts of carbon dioxide, and that's where ethanol's green label starts to brown. Most ethanol plants burn natural gas or, increasingly, coal to create the steam that drives the distillation, adding fossil- fuel emissions to the carbon dioxide emitted by the yeast. Growing the corn also requires nitrogen fertilizer, made with natural gas, and heavy use of diesel farm machinery. Some studies of the energy balance of corn ethanol—the amount of fossil energy needed to make ethanol versus the energy it produces—suggest that ethanol is a loser's game, requiring more carbon-emitting fossil fuel than it displaces. Others give it a slight advantage. But however the accounting is done, corn ethanol is no greenhouse panacea.

"Biofuels are a total waste and misleading us from getting at what we really need to do: conservation," says Cornell University's David Pimentel, who is one of ethanol's harshest critics. "This is a threat, not a service. Many people are seeing this as a boondoggle." But Wietzki and her colleagues in Mead think they can do better. They hope to improve the energy balance and greenhouse gas benefits of ethanol by creating a closed-loop system—which is where those cows come in. They plan to fire their boilers with methane from two giant four-million-gallon biodigesters fed with cattle manure from the feedlot next door—in effect using biogas to make biofuel. The increased efficiency, she says, isn't only good for the environment, it's also good business, especially if the price of corn keeps rising or oil drops below $45 a barrel or so, the lowest price at which ethanol backers say the fuel can compete with gasoline in the U.S. "The last people standing," Wietzki says, "will be highly efficient producers like us."

It's easy to lose faith in biofuels if corn ethanol is all you know. A more encouraging picture unfolds some 5,500 miles southeast of Mead, where the millions of drivers of São Paulo, Brazil, spend hours a day jammed to a standstill in eight lanes of traffic, their engines, if not their tempers, idling happily on álcool from Brazil's sprawling sugar belt. The country had been burning some ethanol in its vehicles since the 1920s, but by the 1970s it was importing 75 percent of its oil. When the OPEC oil embargo crippled the nation's economy, Brazil's dictator at the time—Gen. Ernesto Geisel—decided to kick the country's oil habit. The general heavily subsidized and financed new ethanol plants, directed the state-owned oil company, Petrobras, to install ethanol tanks and pumps around the country, and offered tax incentives to Brazilian carmakers to crank out cars designed to burn straight ethanol. By the mid-1980s, nearly all the cars sold in Brazil ran exclusively on álcool.

Formula One-loving Brazilian drivers embraced the cars, especially since pure ethanol has an octane rating of around 113. It burns best at much higher compression than gasoline, allowing alcohol engines to crank out more power. Best of all, the government subsidies made it significantly cheaper. Not that ethanol didn't hit a few bumps in the road. By the early 1990s, low oil prices led the government to phase out the subsidies, and high sugar prices left the sugar mills, or usinas, with no incentive to produce the fuel. Millions of alcohol car drivers like Roger Guilherme, now a supervising engineer at Volkswagen-Brazil, were left high and dry.

"Guys like me had to wait in long lines two hours or more to fuel up," Guilherme says in his office at the massive Volkswagen plant in São Bernardo do Campo. "Consumers lost confidence in the alcohol program." A decade later when oil prices started to rise, Brazilians wanted to burn alcohol again, but given their past experience, they didn't want to be wedded to it. So Guilherme's bosses gave him a challenge: Find an inexpensive way for one car to burn both fuels. Guilherme's team worked with engineers at Magneti Marelli, which supplies fuel systems to Volkswagen, to write new software for the engine's electronic control unit that could automatically adjust the air-fuel ratio and spark advance for any mixture of gasoline and alcohol. Volkswagen introduced Brazil's first TotalFlex vehicle in 2003, modifying a small soccer ball of a commuter car called the Gol, which means—you guessed it—"goal!" It was an instant hit, and soon every other carmaker in Brazil followed suit. Today, nearly 85 percent of cars sold in Brazil are flex: small, sporty designs that zip around the lumbering, diesel-belching trucks in São Paulo. You can even get a flex Transporter—the beloved loaf-shaped VW van, still made here. With a liter of alcohol running an average of one Brazilian real cheaper than gasoline at the pump, most flex cars haven't burned gas in years. Sugarcane, not engine technology, is the real key to Brazil's ethanol boom. The sweet, fast-growing tropical grass has been a staple export for the country since the 1500s. Unlike corn, in which the starch in the kernel has to be broken down into sugars with expensive enzymes before it can be fermented, the entire sugarcane stalk is already 20 percent sugar—and it starts to ferment almost as soon as it's cut. Cane yields 600 to 800 gallons (2,300 to 3,000 liters) of ethanol an acre, more than twice as much as corn.

Usina São Martinho, one of the largest sugar mills and ethanol distilleries in the world, sits in the heart of the emerald desert, as one São Paulo columnist has dubbed Brazil's prime sugarcane region in central São Paulo state. The rolling fields are carpeted with cane for as far as the eye can see. Each year the mammoth plant turns seven million tons of cane into 300 million liters of ethanol for Brazilian cars and 500,000 tons of sugar, bound mainly for Saudi Arabia. To meet growing demand for ethanol both here and abroad, the company is also building a three-million-ton unit—exclusively for ethanol—in the rapidly expanding cane fields of Goiás state.

Growers in the emerald desert can get seven harvests from their fields before replanting, and the distilleries recycle their wastewater into fertilizer. Like most of Brazil's usinas, São Martinho consumes no fossil fuel or electricity from the grid; for heat and power it burns cane waste, known as bagasse, typically generating a slight surplus of power. Even the cane trucks and agricultural machinery burn a blend of diesel and ethanol, while the favorite crop duster, a hot little plane called the Ipanema, is the first fixed-wing aircraft built to burn pure alcohol. "We're obsessed with efficiency," says plant director Agenor Cunha Pavan.

While corn ethanol's energy ratio hovers around breakeven, "we get eight units of ethanol for every one unit of fossil fuel," says Isaias Macedo, one of Brazil's leading sugarcane researchers. Experts estimate that producing and burning cane ethanol generates anywhere from 55 to 90 percent less carbon dioxide than gasoline. And Macedo envisions even greater efficiencies. "We can do the same thing with two-thirds or half of the bagasse, better manage tractors in the field, and approach levels of 12 or 13."

Even sugarcane isn't without its problems. While nearly all of São Martinho's cane is machine harvested, most Brazilian cane is cut by hand; the work, though well paid, is hot, dirty, and backbreaking. Cutters die of exhaustion every year, say leaders of their union. And to kill snakes and make the cane easier to cut by hand, the fields are usually burned before harvest, filling the air with soot while releasing methane and nitrous oxide, two potent greenhouse gases.

The expansion of Brazil's cane acreage—set to nearly double over the next decade—may also be contributing to deforestation. By displacing ranching in existing agricultural areas, sugar may be adding to the pressures that send cattlemen deeper into frontier territory like the Amazon and the biologically diverse savannas known as the cerrado. "If alcohol is now considered a 'clean' fuel, the process of making it is very dirty," says Marcelo Pedroso Goulart, a prosecutor for the Public Ministry of São Paulo. "Especially the burning of cane and the exploitation of the cane workers." Every biofuel also consumes crops that could be feeding a hungry globe. A recent UN report concludes that although the potential benefits are large, the biofuels boom could reduce food security and drive up food prices in a world where 25,000 people die of hunger every day, most under age five. Demand for both fuel and food is expected to more than double by mid-century, and many scientists fear that in coming decades, climate change will undermine agricultural productivity. "Agriculture should be used to stop the hunger of the people. If one person were hungry, this would be a shame," says Goulart. "There are millions who are hungry in Brazil, and this monoculture does not help."

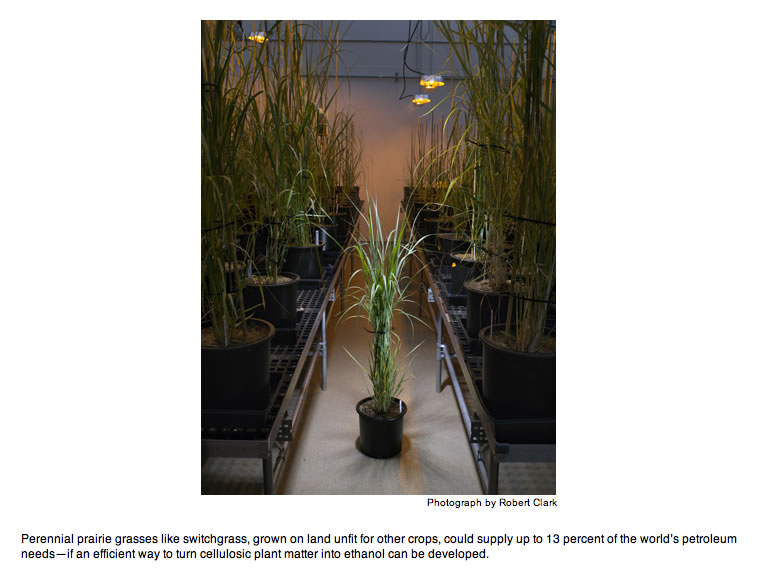

The only way to reap the benefits of biofuels without squeezing the food supply is to take food out of the picture. Though corn kernels and cane juice are the traditional sources of ethanol, you can also make it from stalks, leaves, and even sawdust—plant by-products that are normally dumped, burned, or plowed back under. These materials are mostly cellulose, the tough chains of sugar molecules that make up plant cell walls. Breaking up those chains and fermenting the sugars could yield a cornucopia of biofuels, without competing with food crops. Biofuel visionaries picture a resurgence of deep-rooted perennial prairie grasses like switchgrass or buffalo grass, sequestering carbon in the soil, providing wildlife habitat and erosion control, and supplying a bounty of homegrown fuel.

The principle behind cellulosic ethanol is simple. Making it as cheap as gas isn't.

So far, only a few pilot plants are making ethanol from cellulose in the U.S. A small operation at the National Renewable Energy Lab (NREL) in Golden, Colorado, has been running the longest. It can convert a ton of biomass—shredded cornstalks, switchgrass, wood—into 70 gallons (265 liters) of ethanol in about a week. Along with cellulose and hemicellulose, these feedstocks all contain a substance called lignin. Lignin binds the cellulose molecules together, giving plants the structural strength to stand up and catch the sun. The gluey lignin also makes plant matter hard to break down, as the pulp and paper industry is well aware. "The old joke is you can make anything from lignin but money," says Andy Aden, a senior researcher on the ethanol project.

To unlock the cellulose molecules from the lignin, the feedstock is often pretreated with heat and acid. Then it's mixed with high-tech enzymes to break down the cellulose into sugars. The resulting dark brown goo, with a slightly sweet, molasses-like aroma, is fed into fermentation tanks where bacteria or yeast go to work to make the alcohol. The current process turns just 45 percent of the energy content in the biomass into alcohol, compared with an oil refinery, which extracts 85 percent of the energy in crude oil. The efficiency will have to improve for cellulosic ethanol to compete with gasoline, and researchers are looking for better cellulose-busters. One possibility: genetically modified microbes and enzymes from the guts of termites—nature's own cellulosic energy factories.

The potential, however, is huge. Exploiting the cellulose in corn plants, rather than just the kernels, could double corn's ethanol yield; switchgrass could produce as much ethanol per acre as sugarcane. A 2005 study by the U.S. Department of Agriculture and the U.S. Department of Energy estimated that by boosting farm productivity and planting 50 million acres (20 million hectares) of fallow land with perennial grasses and fast-growing trees, the U.S. could produce 1.3 billion tons (about 1.2 billion metric tons) of feedstock for ethanol. Separately, NREL calculated that all that plant matter could replace more than half the transportation fuel currently burned each year. Mike Pacheco, former director of NREL's Bio-energy Center, pulls out a chart from that study. "The green line is what we think we can make on farms and from trees and switchgrass"—the equivalent of 3.5 billion barrels of oil.

Pacheco traces another line on his chart, at twice the altitude of the first. It represents the ultimate biofuels dream: enough green fuel to make the U.S. energy independent. It is where we might be, says Pacheco, if we greatly increase vehicle efficiency while churning out cellulosic ethanol, or, more tantalizing, "if we make algae work." There is no magic-bullet fuel crop that can solve our energy woes without harming the environment, says virtually every scientist studying the issue. But most say that algae—single-celled pond scum—comes closer than any other plant because it grows in wastewater, even seawater, requiring little more than sunlight and carbon dioxide to flourish. NREL had an algae program for 17 years until it was shut down in the mid-1990s for lack of funding. This year the lab is cranking it back up again. A dozen start-up companies are also trying to convert the slimy green stuff into a viable fuel.

GreenFuel Technologies, of Cambridge, Massachusetts, is at the head of the pack. Founded by MIT chemist Isaac Berzin, the company has developed a process that uses algae in plastic bags to siphon carbon dioxide from the smoke-stack emissions of power plants. Algae not only reduce a plant's global warming gases, but also devour other pollutants. Some algae make starch, which can be processed into ethanol; others produce tiny droplets of oil that can be brewed into biodiesel or even jet fuel. Best of all, algae in the right conditions can double in mass within hours. While each acre of corn produces around 300 gallons (1,135 liters) of ethanol a year and an acre of soybeans around 60 gallons (227 liters) of biodiesel, each acre of algae theoretically can churn out more than 5,000 gallons (19,000 liters) of biofuel each year.

"Corn or soybeans, you harvest once a year," says Berzin. "Algae you harvest every day. And we've proved we can grow algae from Boston to Arizona." Berzin's company has partnered with Arizona Public Service, the state's largest utility, to test algae production at APS's natural-gas-burning Redhawk power plant just west of Phoenix. Algae farms around that one plant, located on 2,000 acres (809 hectares) of bone-dry Sonoran Desert, could double the current U.S. production of biodiesel, says Berzin.

The energy farm, as GreenFuel calls it, isn't much to look at, just a cluster of shipping containers and office trailers next to a plastic greenhouse structure longer than a football field and perhaps 50 feet (15 meters) wide. Outside the greenhouse, rows of large plastic tubes filled with bubbling bright green liquid hang like giant slugs from hooks. After making a few calls to his boss, GreenFuel's security-conscious head of field operations, Marcus Gay, allows me to inspect this "seed farm," which grows algae for the greenhouse. Everything else is off-limits. The company guards its secrets closely.

With good reason: Only perhaps a dozen people on the planet know how to grow algae in high-density systems, says Gay. Algae specialists, long near the bottom of the biology food chain, are becoming the rock stars. Two of Arizona's largest universities recently started algae programs. Their biggest challenge, as with cellulosic ethanol, is reducing the cost of algae fuel. "At the end of the day for this to work, this has to be cheaper than petroleum diesel," says Gay. "If we're one penny over the cost of diesel per gallon, we're sunk." (In July, rising costs and technical problems forced GreenFuel to shut down the Redhawk bioreactor temporarily.)

Hard numbers—supply, efficiency, and, most important, price at the pump—will determine the future of ethanol and biodiesel. But for now green fuels have an undeniable romance. In the garage of his office complex in downtown Phoenix, Ray Hobbs, a senior engineer for APS who is leading the company's fuel initiative, walks past a small fleet of electric cars, hybrids, even a hydrogen-powered bus. He climbs into a big diesel Ford van and turns the key. The exhaust, unlike a typical diesel's, is invisible, with just the faintest whiff of diesel smell from the algae biodiesel made at the Redhawk pilot plant. The superslick plant oil has also quieted a little of that annoying diesel rattle.

"The way I think about these things is I'm sitting in a river in a canoe," says Hobbs. "Now do I want to paddle upstream, or do I want to go with the flow? Algae is downstream, with the flow. We have processes in nature that are honed for us, that have evolved. So we can take those processes and make them faster and more efficient and harness that power. We can't wait generations to screw around with this. We have to do it now."

Hobbs says he has fielded dozens of calls from power companies interested in building an algae plant of their own to scrub emissions and help meet their renewable fuels mandate. The lure of plant fuels even seems to have reached the petroleum-rich sands of the Middle East, where the United Arab Emirates has launched a 250-million-dollar renewable energy initiative that includes biofuels—perhaps a sign that even the sheikhs now realize that the oil age won't last forever. As precedents for such collective effort, people sometimes point to the Manhattan Project to build a nuclear weapon or the Apollo Program to put a man on the moon. But those analogies don't really work. They demanded the intense concentration of money and intelligence on a single small niche in our technosphere. Now we need almost the opposite: a commitment to take what we already know how to do and somehow spread it into every corner of our economies, and indeed our most basic activities. It's as if NASA's goal had been to put all of us on the moon.

Not all the answers are technological, of course—maybe not even most of them. Many of the paths to stabilization run straight through our daily lives, and in every case they will demand difficult changes. Air travel is one of the fastest growing sources of carbon emissions around the world, for instance, but even many of us who are noble about changing lightbulbs and happy to drive hybrid cars chafe at the thought of not jetting around the country or the world. By now we're used to ordering take-out food from every corner of the world every night of our lives— according to one study, the average bite of food has traveled nearly 1,500 miles before it reaches an American's lips, which means it's been marinated in (crude) oil. We drive alone, because it's more convenient than adjusting our schedules for public transit. We build ever bigger homes even as our family sizes shrink, and we watch ever bigger TVs, and—well, enough said. We need to figure out how to change those habits.

Probably the only way that will happen is if fossil fuel costs us considerably more. All the schemes to cut carbon emissions—the so-called cap-and-trade systems, for instance, that would let businesses bid for permission to emit—are ways to make coal and gas and oil progres- sively more expensive, and thus to change the direction in which economic gravity pulls when it applies to energy. If what we paid for a gallon of gas reflected even a portion of its huge environmental cost, we'd be driving small cars to the train station, just like the Europeans. And we'd be riding bikes when the sun shone.

The most straightforward way to raise the price would be a tax on carbon. But that's not easy. Since everyone needs to use fuel, it would be regressive—you'd have to figure out how to keep from hurting poor people unduly. And we'd need to be grown-up enough to have a real conversation about taxes—say, about switching away from taxes on things we like (employment) to taxes on things we hate (global warming). That may be too much to ask for—but if it is, then what chance is there we'll be able to take on the even more difficult task of persuading the Chinese, the Indians, and all who are lined up behind them to forgo a coal-powered future in favor of something more manageable? We know it's possible—earlier this year a UN panel estimated that the total cost for the energy transition, once all the pluses and minuses were netted out, would be just over 0.1 percent of the world's economy each year for the next quarter century. A small price to pay.

In the end, global warming presents the greatest test we humans have yet faced. Are we ready to change, in dramatic and prolonged ways, in order to offer a workable future to subsequent generations and diverse forms of life? If we are, new technologies and new habits offer some promise. But only if we move quickly and decisively—and with a maturity we've rarely shown as a society or a species. It's our coming-of-age moment, and there are no certainties or guarantees. Only a window of possibility, closing fast but still ajar enough to let in some hope.